The Main Challenges of a Supply Chain Digitization

First appeared on medium

Supply chain and logistics is a complex assortment of processes that can no longer be managed without digitization. Consider large retail stores such as Alibaba or Amazon. They do not stock actual inventories, but they supply to millions of consumers and businesses around the world every month. Factor in the management of hundreds of thousands of product suppliers, and you begin to grasp the scale at which these companies operate. It is no longer practical to do things the old-fashioned way.

From UPS looking to provide 3D printing services at its stores to Amazon testing out deliveries through drones, all major companies around the world are moving towards the digitization of their supply chains. The transition towards a digital economy is perhaps the largest and most radical change in the history of economics, and it has transformed the way businesses operate. It has — and will continue to — change the way we design, plan, manufacture, ship, and operate products and assets.

Large-scale digitization of supply chains, however, come with their own sets of challenges.

Challenges in a Digital Supply Chain

A major challenge in the digitization of the supply chain is the lack of understanding and adequate preparation. Most business owners agree that digital the economy will impact their business. However, a very small fraction have plans to adopt. Despite the rapid digitization in the last decade or so, many companies are still at an early stage of digital maturity.

So how does the digital economy impact businesses? The answer to this question is beyond the scope of digital transactions alone. Thanks to increased awareness and buying power, consumers are increasingly demanding more and more products that are better and customized to individual needs. It calls for a dynamic supply chain that can cater to their requests in the shortest time possible.

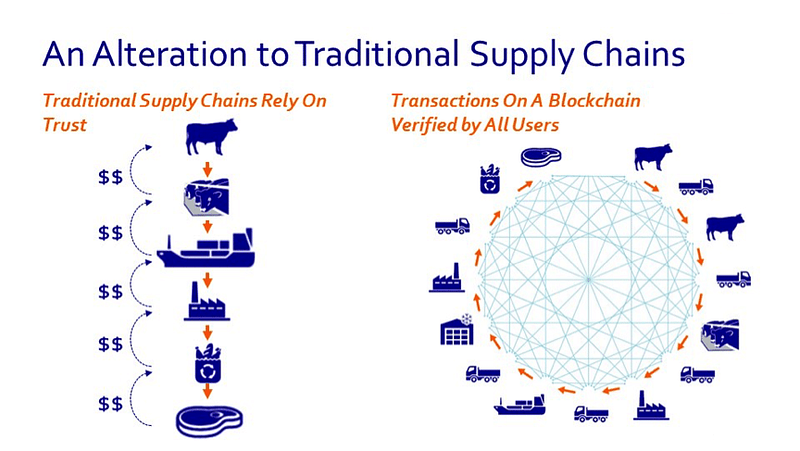

Then there is the financial aspect itself. The concept of digital transactions is not a new one and has been around for many decades. However, technologies developed in recent history, namely blockchain, have transformed the idea of digital currencies towards more secure and decentralized peer-to-peer payment networks. While the idea of payment through cryptocurrencies has still not become mainstream, it is only a matter of time before the blockchain disrupts the supply chain process for good.

While the digitization of supply chains has automated many processes, it hasn’t adequately answered questions such as where does a product originate from? Who is the real owner of a product? Is a certain product genuine or counterfeit? All these questions challenge the integrity of a supply chain network.

Consider the example of a smartphone manufacturer that assembles different components and relies heavily on networks that supply integrated circuits, computing chips and so on. Does the manufacturer know for sure whether a mobile CPU is a genuine ARM product or a replica? Chip manufacturers, in turn, rely on their supply networks for semiconductor materials, transistors, and other components. Can they trace the origin of a faulty transistor or an impure semiconductor?

All the parties involved in the manufacture of a smartphone, from raw material providers to chip manufacturers to electronic component suppliers all the way up to the manufacturers themselves might have some form of digitization in their system, but there is no unanimous agreement on standards for information sharing. Companies are reluctant to let go of the control of their data or adapt to the standards set by another company. As a result, there are many unknowns in the equation. At any point in the entire supply chain, data can be changed, manipulated or corrupted, resulting in a bad, faulty or counterfeit product reaching end consumers.

The Solution

There is no generally accepted solution to these supply chain problems. However, blockchain is a technology that potentially holds a lot of promise. Blockchain is a decentralized, distributed ledger technology that can be used to record transactions, establish the authenticity of value items and trace the origin of each product down to its raw materials. It will make the entire supply chain much more transparent and highly resistant to data manipulation and corruption.

Blockchain is already being implemented to transform supply chain networks. Companies such as Walmart and Starbucks have deployed their blockchains to establish the originality of their products and track the origin of faulty, substandard or counterfeit products and raw materials.

The implications of this are enormous. If supply chains around the world were to adopt blockchain, it would transform the way goods and services are delivered. Food and healthcare items can be made safer, counterfeiting of fashion and luxury goods can be reduced, authentic ownership of goods can be established to prevent theft — the possibilities are limitless. All this will ultimately drive global industries towards more transparency and ethical practices.